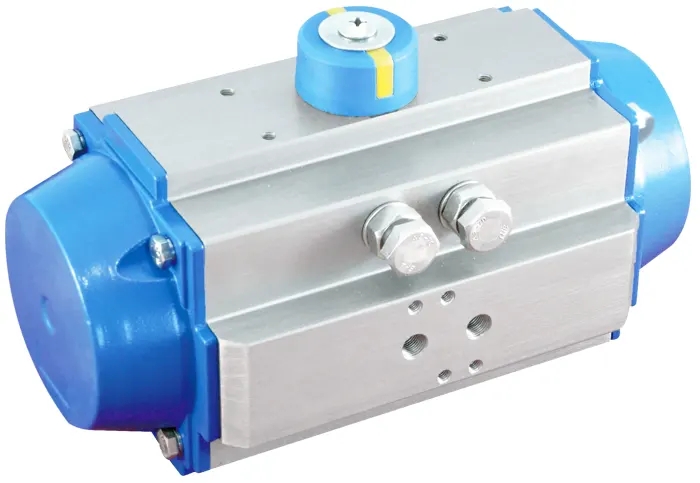

ACTUATOR – Pneumatic

KRP series is a reliable, economical and long-life rack-and-pinion pneumatic actuator provided by KLINGER, which can be used for quarter-turn rotary valves such as ball valves, butterfly valves, and plug valves.

CONTACT SALES

KLINGER Shanghai

500 Mingnan Road, Songjiang District, Shanghai, China

Valve & Level Gauge Department

Keyaccount@klinger-shanghai.com